Pedestal Crane Slew Ring

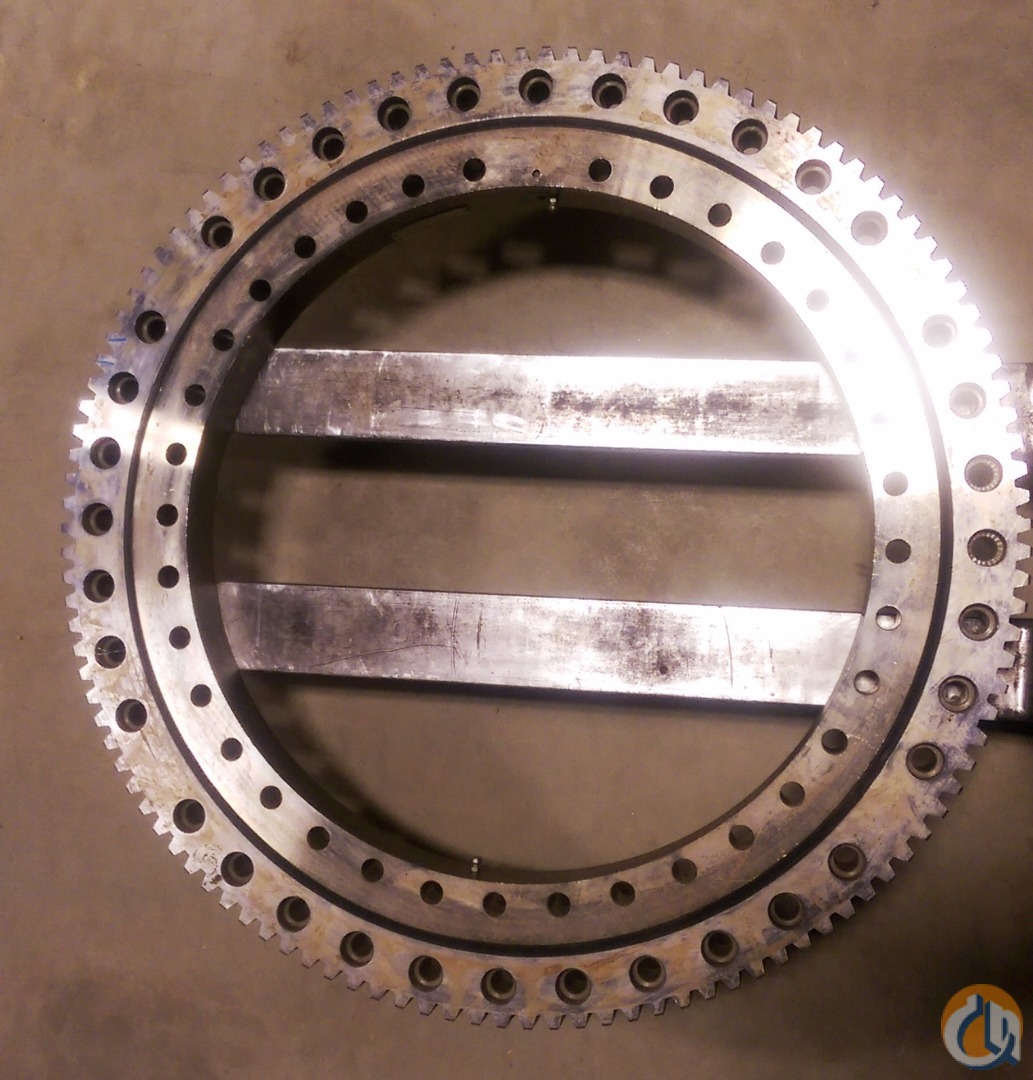

We have manufactured offshore pedestal mounted crane deck crane slew ring bearing mounted with capacity ranging from 5mt to 50mt and boom length up to 60 meters.

Pedestal crane slew ring. The worm is driven by the motor which drives the outer ring of the slewing ring to rotate. Light flanged greased slewing ring bearing for pedestal crane 5 0 reviews packaging bottling industry are synonymous of high productivity link with very high technology process xuzhou wanda slewing bearing co ltd has developed in accordance with those high requirements slewing rings with large diameters for higher higher productivity and. These cranes are completely enclosed and designed for long operational life low operating costs and minimum maintenance requirements. A slewing bearing or slew ing ring is a rotational rolling element bearing that typically supports a heavy but slow turning or slow oscillating load often a horizontal platform such as a conventional crane a swing yarder or the wind facing platform of a horizontal axis windmill.

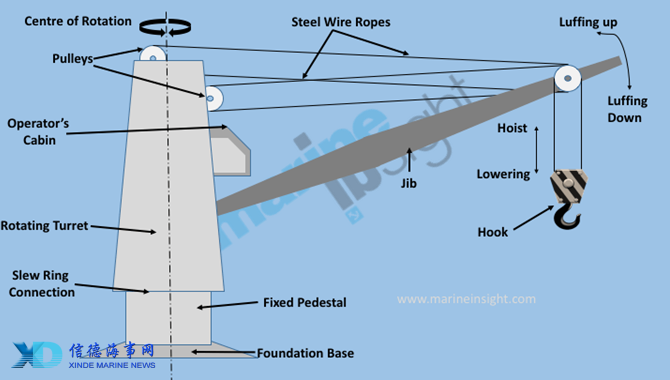

1 slewing bearing is a kind of comprehensive load which can be withstand the larger axial and radial load and tilting moment. Slewing rotating turret slew ring connection fixed pedestal fig 1 the general movement of a pedestal crane wire ropes structures machinery usually a hoist wire and a luffing wire although on some cranes the luffing of the jib might be by means of one or two hydraulic cylinders and various ancillary equipment. Effer can satisfy all your needs both if you want a rack and pinion crane and a slewing bearing crane. The outer ring output the torque through the flange and the inner ring of the slewing ring is fixed in the housing.

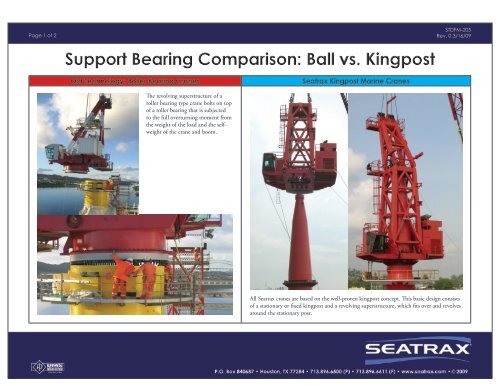

Effer rack system ensures a crane rotation angle exceeding 360 that on average is one of the widest in its category. 32 33 meter working radius. On the other hand the slewing ring system allows the crane to rotate continuously and without limits. An offshore crane is defined as a pedestal mounted elevating and rotating lifting device used to transfer materials and personnel to or from marine vessels barges and structures according to api spec 2c a standard used to design and manufacture offshore cranes.

To slew means to turn without change of place compared to other rolling element bearings slewing bearings. The crane is designed for efficient and accurate offshore sub sea load handling of general cargo at max. Slewing drive has reverse self locking because of worm gear drive with reverse self locking characteristics. The slew drive working principle.

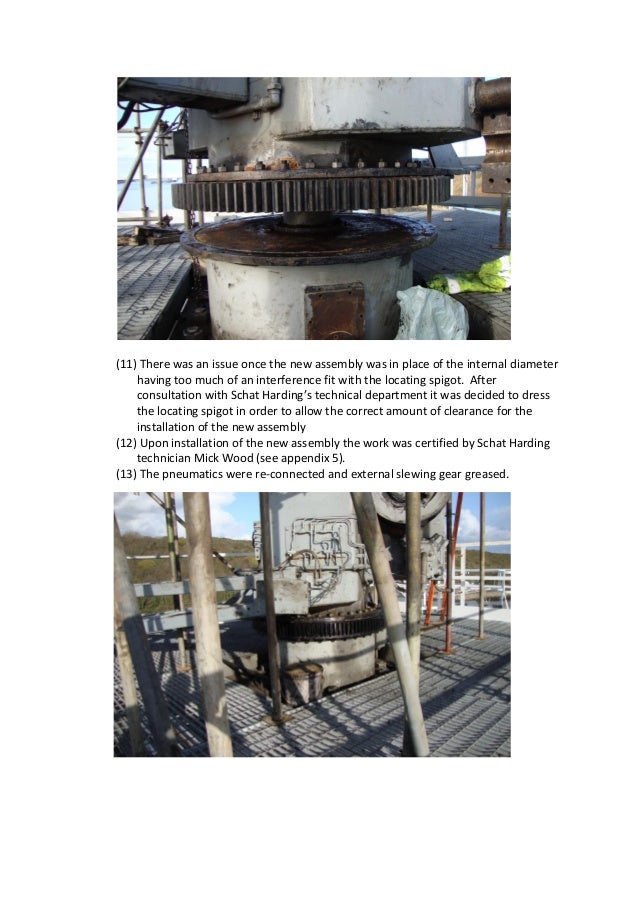

Alatas singapore recently carried out the replacement of four sets of crane slew ring bearings for mitsubishi deck cranes at our singapore anchorage. The crane is designed with a general crane dynamic factor of 1 4 and a pedestal slew ring fasteners is designed with dynamic factor of 2 0 according to dnv requirement for offshore crane.