Pdf Laser Beam Welding

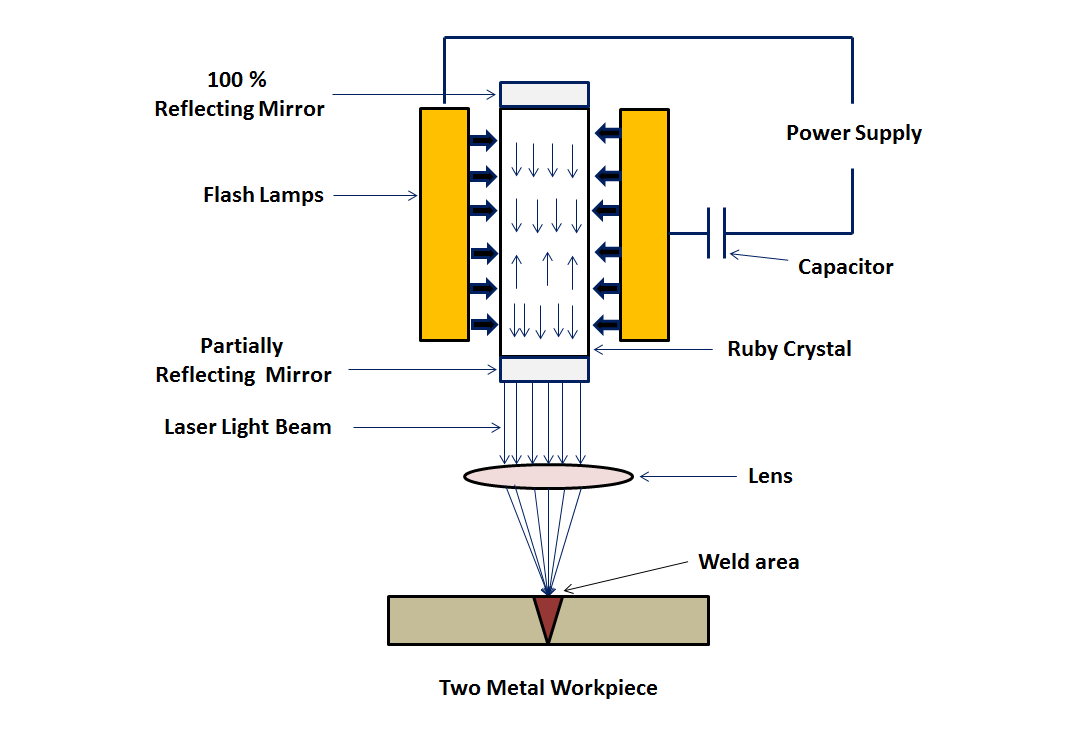

Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

Pdf laser beam welding. 116 00 this document presents recommended practices for laser beam welding cutting and allied processes. The energy of a narrow laser beam is highly concentrated at 10 8 10 10 w cm 2 so a weak weld pool is formed very rapidly for about 10 6 sec. Printed hard copy download pdf. Download laser beam welding seminar reports ppt pdf laser beam welding seminar topics abstracts full documentation source code.

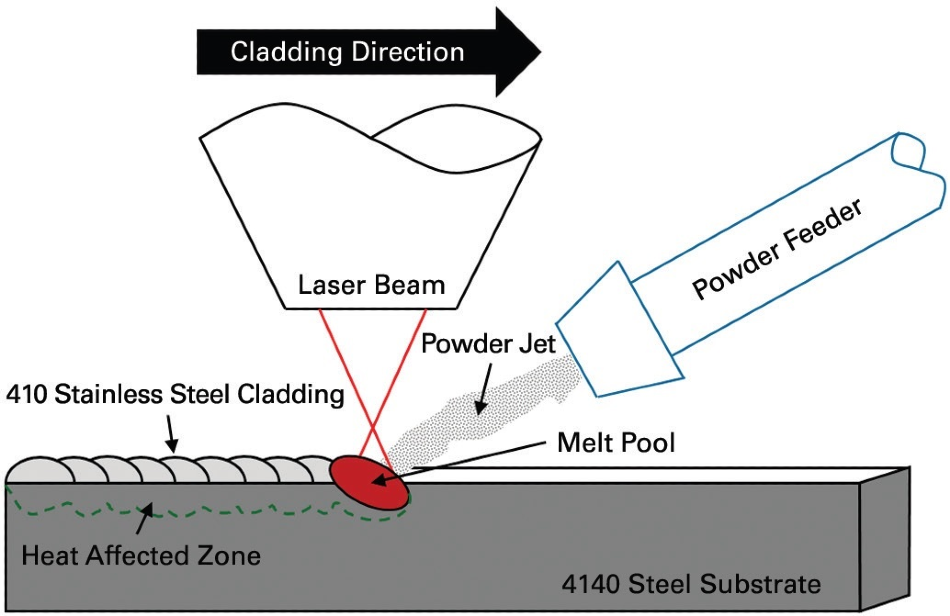

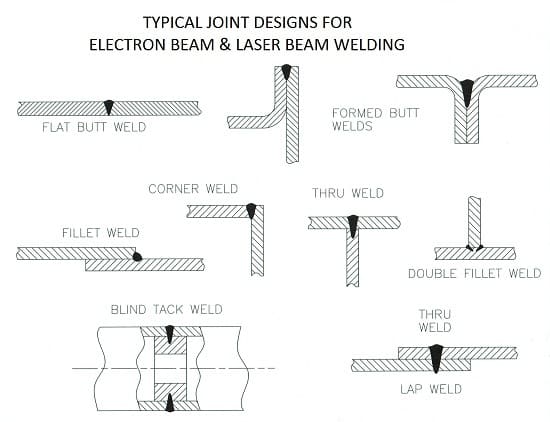

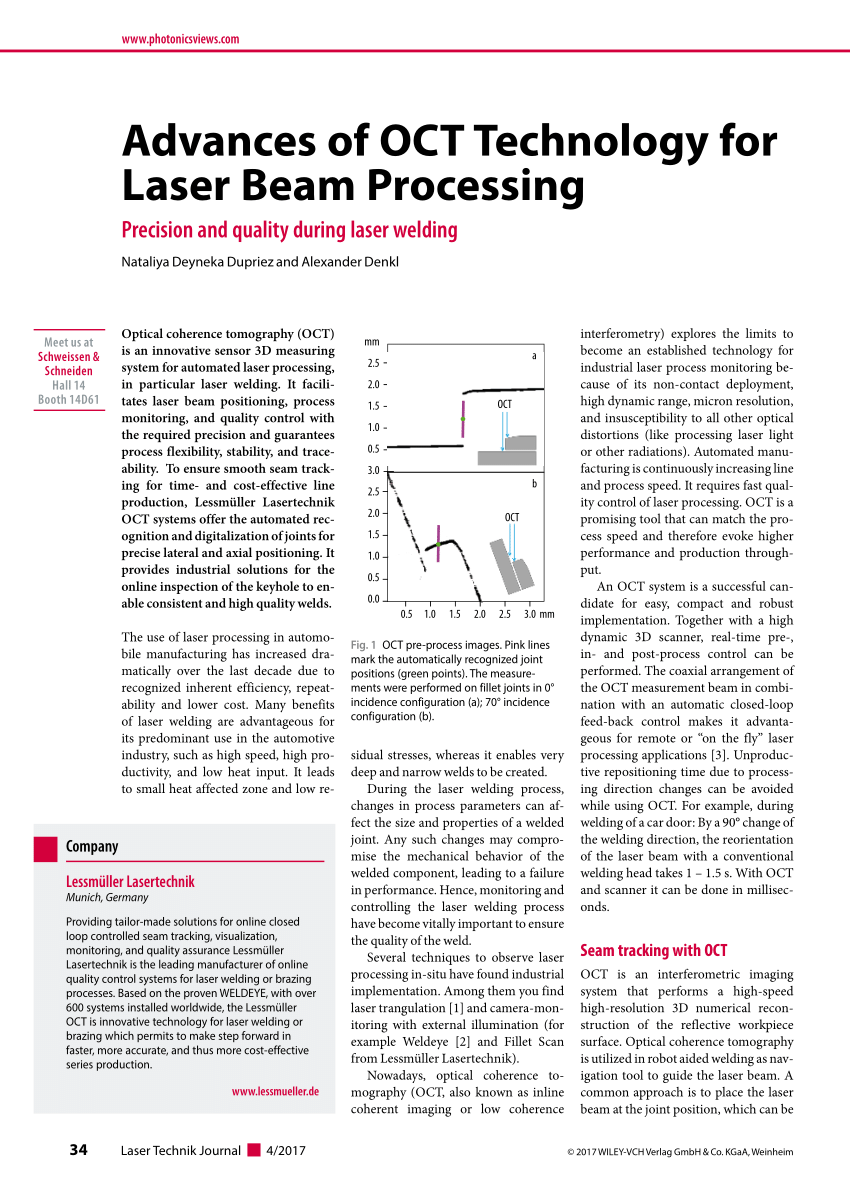

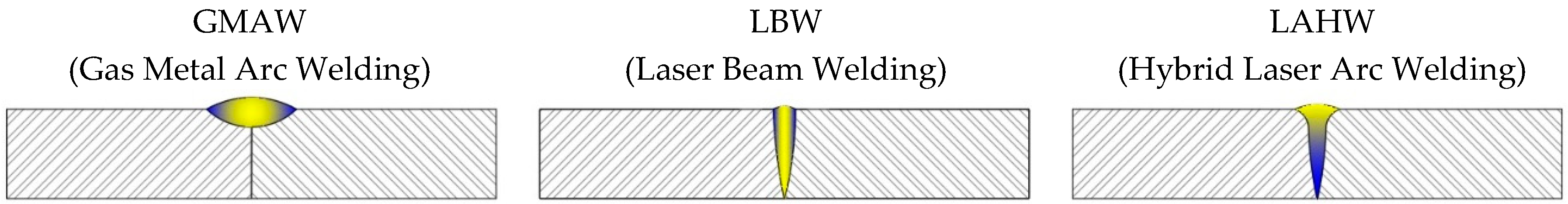

Laser welding is a process used to join together metals or thermoplastics using a laser beam to form a weld. Laser beam welding lbw is a welding process in which heat is generated by a high energy laser beam targeted on the workpiece. The laser beams are focused to the cavity between the two metal pieces to be joined. It is intended to cover common applications of the process.

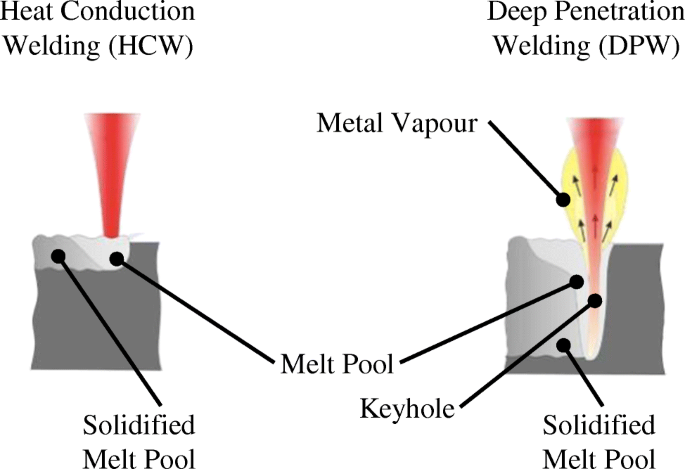

Humans can only see visible or the white light wavelengths. Laser may be recirculated in some cases to reduce cost. Being such a concentrated heat source in thin materials laser welding can be carried out at high welding speeds of metres per minute and in thicker materials can produce narrow deep welds between square edged parts.

Laser beam welding lbw is a welding technique used to join pieces of metal or thermoplastics through the use of a laser the beam provides a concentrated heat source allowing for narrow deep welds and high welding rates. Laser is an acronym for light amplification by stimulated emission of radiation. C7 2m 2010 recommended practices for laser beam welding cutting and allied processes formats. Continuous wave gas lasers using carbon dioxide gas with power up to 20 kw are used for laser beam welding.

Laser beam welding lbw is a fusion joining process that produces coalescence of materials with the heat obtained from a concentrated beam of coherent monochromatic light impinging on the joint to be welded. Laser welding a laser is a beam of concentrated light energy generated at a specific wavelength. Welding is done with high power lasers with longer pulses so that metal can be heated to its melting point without vaporization. In nature light exists across a spectrum of wavelengths ranging from very short x rays and gamma rays to very long radio waves.

The process is frequently used in high volume applications using automation as in the automotive industry it is based on keyhole or penetration mode welding. The laser beam heats and melts the edges of the workpiece forming a joint.